| About Us | Contact Us | Testimonials | File Specs. | Printing 101 | Find Designer | Templates | Glossary | FAQ | Login |

|

|

Printing 101Baby Steps To Print Purchasing Know HowThe Printing Crash Course - Printing School

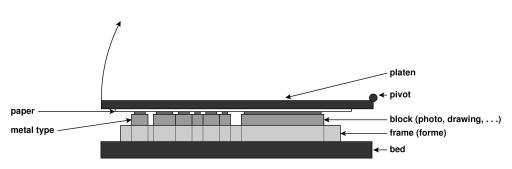

Letterpress PrintingLetterpress is one of the oldest technologies utilized to print. Letterpress printing is achieved by inking raised metal (usually lead) images and type that is transferred to a paper with slight pressure. Larger type is usually made of hardwood. Pictures and drawings are converted to raised etchings that are mounted on to wooden blocks. All the manually assembled monotype (also called cold type) images and photographs are locked up in a rectangular frame called a Chase. The proof is derived from the chase on a proofing press, and corrections are made to the type and image assembly. As is obvious, the image on the printed paper has a relief, and if care is not taken, then the deformation of the paper will occur, especially when printed on both sides of the sheet. Letterpress is normally used mostly for one color printing these days, and very rarely for two color printing. More common use of this process of print is utilized in the sequential numbering of forms and invoices where the pressure from the imaging platen or cylinder depresses the mechanical portion of a numbering machine, thereby changing the digit by one each impression, thus achieving sequential numbering on a printed job. Metal rules whether straight for scoring or perforation can be locked up into the chase for the desired effect to the printed piece. To produce cheap printing for Brochures, Sell Sheets, Flyers, Leaflets, Business Cards, Post Cards etc., this process proves to be too old and too expensive to be utilized for these items.

| |

Copyright © www.printoutlet.us

Date Updated: Wednesday 16th of April 2025 01:07:32 PM

US Website

US Website  Canadian Website

Canadian Website